Sure, you’re familiar with hard hats, earplugs and other personal protective equipment (PPE) to keep you safe at work. What you may not realize is that the Occupational Safety and Health Administration (OSHA) says other measures should play the primary role in keeping workers from hazards. OSHA’s tiered approach to workplace protection, aka its hierarchy of controls, puts the main responsibility for engineering and workplace controls. PPE, while crucial, should be the final line of defense in keeping you – or your workers – safe.

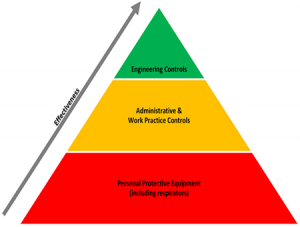

In its hierarchy of controls, OSHA outlines three lines of defense for keeping workers safe on the job.

Image By OHSA https://goo.gl/images/IpzdMX

Engineering controls

Simply put, engineering controls require a physical change in the workplace to reduce hazards. The ideal way to keep workers safe according to OSHA is to eliminate or substitute the hazard altogether. When that’s not possible, then employers need to change operations in their workplace. For example, in settings where chemicals are a potential hazard, the employer should implement a local exhaust ventilation system to limit employee exposure.

Workplace & Administrative Controls

The second line of defense – workplace and administrative controls – require the worker or employer to do something. This safeguard is all about putting the right policies and procedures in place. Workplace controls can include good housekeeping or periodic inspections. Administrative controls influence the way workers perform a task. In the chemical hazard example, this could include rotating job assignments or adjusting work schedules so that workers aren’t overexposed to a certain chemical.

Personal Protective Equipment (PPE)

Last but certainly not least, PPE is the final line of defense in OSHA’s hierarchy and requires the worker to wear something. When the first two safeguards aren’t feasible or don’t give enough protection then “employers must provide personal protective equipment to their workers and ensure its proper use.” Workers across many industries know their way around gear like gloves, safety glasses, earplugs and more to keep them safe on the job but OSHA requires employers to follow certain standards to make sure PPE is the most effective.

Make PPE Work For You Not Against

Since it’s the last barrier of protection keeping you from getting hurt, you’ll probably want to make sure that you – and your employees – are PPE masters. To keep you covered, OSHA outlines general industry requirements for PPE in its 1910.132 Standard. Here you’ll find that employers are responsible for ensuring employees have the right PPE at no cost, that they’re trained in understanding how to use it, and that it’s properly maintained. Many categories of PPE need to meet or be equal to standards developed by the American National Standards Institute (ANSI).

Keeping employers accountable, OSHA gives citations when their workplaces don’t meet its standards for PPE. For example, OSHA has cited:

- 1910.132(a) for failure to provide and ensure the use of flame-resistant clothing necessary to protect employees from burns due to flash fires.

- 1910.132(b) for failure to ensure that employee-owned flame-resistant clothing is properly maintained and sanitary.

- 1910.132(c) for failure to provide flame-resistant clothing that is of safe design and construction for the work being performed.

You can ensure that your workplace meets OSHA standards by following the hierarchy of controls and purchasing the right PPE. The Working Person’s Store offers a wide selection of PPE that meets ANSI and OSHA requirements. You’ll find flame resistant clothing, high visibility vests, steel-toed boots, safety glasses and more.