Your work is tough, but choosing your footwear shouldn’t be. If you’ve ever had a difficult time navigating footwear terminology, you’re not alone.

Different types of construction, safety features, and even toe protection might have you wondering what kind of work shoes you really need to invest in for your line of work.

Here are some of the most common work boot terms to help you make the best decision!

Safety Toe Protection

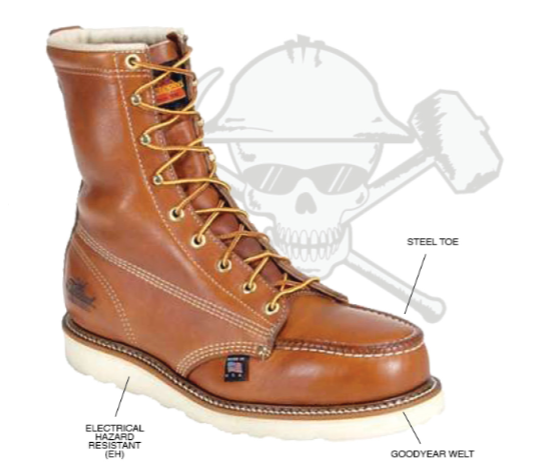

– Steel toe boots are the most common type of protection. Boots with steel toe caps safeguard electricians, construction, manufacturers, and anyone who works in environments prone to falling objects.

– Composite toe caps are lighter than steel toe caps, often by about 30%. They don’t contain any form of metal but use a composite material to protect your toes. These lightweight, non-metallic boots are best for people who go through metal detectors on a regular basis, like security personnel or airport employees. The composite material does not conduct cold or heat like steel, so this may be also be a better option if you work in extreme temperatures.

– Aluminum or alloy safety toes are also lighter than steel toe caps but give your toes more space to breathe than steel. On the flip side, aluminum toe cap boots can be a little more expensive than steel toe boots and can also set off metal detectors.

Safety Standards

Your work boots should have information labels which will include any safety standards they meet. The American Society for Testing and Materials (ASTM) sets the standards and testing procedures for safety footwear. The first line of the label lists the standard applied when testing those boots. Other terms you will see include:

- I/75: Impact resistance (I) and its rating (75, 50, or 30 lbs.) for the toe area

- C/75: Compression resistance (C) and its rating (75, 50 or 30 lbs.) for the toe area

- Mt/75: Metatarsal guard and its rating (75 foot-pounds)

- EH: Electrical hazard resistance

- SD: Static Dissipative properties

- PR: Puncture resistance properties of the bottom of the footwear

Construction

How your boots are put together impact how they move with and support you. In the Goodyear welt construction, a ribbon of leather or rubber is stitched to the boot upper, insole, and lining in one piece; the outsole is stitched to the bottom of the welt.

If durability is a top priority for you, Goodyear welted boots are a good option. They don’t provide as much flexibility as some of your other options, however.

In direct attach construction, the outsole of the boot is bonded directly to the sole which gives it extra flexibility and comfort.

In cement construction, the outsole/midsole unit of the boot is bonded to the upper with a high-strength adhesive. This process helps cut weight and provides a narrower profile for the boot. These boots are known for their lighter weight flexibility.

Finding the right pair of boots is an investment in yourself. Choosing the footwear that can stand up to the demands of your job can help protect you against pain and injury. Visit WorkingPerson.com and view our selection from top brands like Wolverine, Caterpillar, Merrell, and more.